Job Stories

Material handling is one of the fastest growing sectors of automation. Learn how Macron's X/Z gantry system solution provided KwikPall founder Steve Ross with a small, standard palletizing machine at an affordable price point.

Material handling is one of the fastest growing sectors of automation. Having worked in the robotics industry for over 30 years, KwikPall founder Steve Ross created custom designs and built palletizing solutions. Unfortunately the price point for these types of systems are often too high, and designs can be complex and require a large amount of floor space.

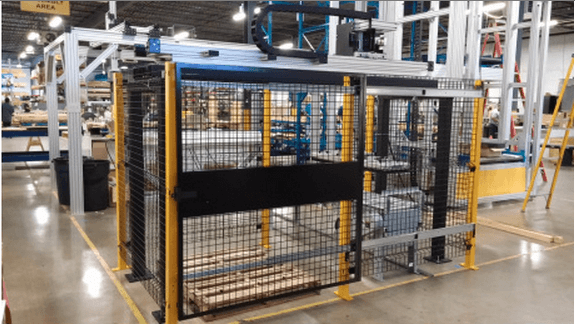

Ross identified a need for a small standardized palletizing solution that fit the price point for small to mid-sized companies looking for a one year payback, and engineered a simple, low maintenance palletizer machine named the KwikPall 150-15 – an economic palletizing or depalletizing system that moves rows or layers of material rather than individual boxes.

With these requirements in mind, Macron Dynamics recognized a 2-axis solution for palletizing that met all of Ross’s needs to construct the KwikPall system. Using a 2 axis gantry that picks up a layer or row of boxes at a time rather than a single single box, pail or tote, Macron Dynamics provided an economic X/Z motion solution, the UC2 gantry system.

Macron’s UC2 gantry helps KwikPall systems palletize and depalletize:

Macron’s UC2 gantry helps KwikPall systems palletize and depalletize:

• 150 lbs at a time

• 15 cycles per minute

• 75 boxes per minute

• At a low price point and footprint

Ross chose to integrate the Macron UC2 gantry system to achieve the X/Z motion required for the automated palletizer to achieve the best price and performance, due to the linear robot’s:

• Simple, low maintenance design

• Reliability and overall quality

• Small footprint

• Payload capabilities

KwikPall had several unique requirements that Macron Dynamics was able to fulfill with their standardized X/Z gantry system. Floor space and overhead is typically large for automated pal-letizing applications, but KwikPall systems are designed with a small footprint thanks to a simple X/Z linear robotic design. With no need for a 3rd or 4th axis, there are less parts, leading to a smaller, simpler solution.

The solution also requires no special programming. Many palletizing systems require high-tech capabilities in-house to operate machinery, while the KwikPall can easily and safely be set up, programmed and operated by a single person in minutes with basic training using the unique KwikWare software on a touch screen.

Although Macron’s UC gantry line is a standardized linear robotic line, the simple design pro-vides a range of benefits including flexibility and expandability in travel lengths and payloads, offering multi-uses and incorporation into larger systems. The heavy duty design of the UC’s are made to last, with the UC2 life expectancy for the KwikPall system expected to last a minimum of 10 years, running 2 shifts per day with 99.9% reliability uptime.

Although Macron’s UC gantry line is a standardized linear robotic line, the simple design pro-vides a range of benefits including flexibility and expandability in travel lengths and payloads, offering multi-uses and incorporation into larger systems. The heavy duty design of the UC’s are made to last, with the UC2 life expectancy for the KwikPall system expected to last a minimum of 10 years, running 2 shifts per day with 99.9% reliability uptime.

UC gantries run at high speeds, and have a range of payload capabilities and travels at a fixed, standardized price and design. Most notably, the Macron UC gantry line offers the flexible ca-pabilities of competitors…at 1/3 the cost.

Customer comments:

Why custom build a solution, when Macron provides a complete X/Z solution that hooks up with my design easily and fast? I’m a big fan of the KISS philosophy – keep it simple…Steve.

For more information on the KwikPall palletizer system, visit the KwikPall website today.

Multi-Axis

Explore how Macron Dynamics engineered a water resistant, belt drive actuator for a Smart Engineering Solutions company for educational use...

Multi-Axis

In search of an automated solution to increase productivity and decrease safety hazards, OES Automation worked with Macron Dynamics to...

Multi-Axis

Explore how Macron Dynamics used an X/Z Heavy Duty Gantry System for a beverage industry customer’s pick and place packaging...